Spring Torque Device from Reell Helps Xerox® Make Cleaner Copies

Spring Torque Device from Reell Helps Xerox® Make Cleaner Copies

ST. PAUL, MN – When global copier giant, Xerox® Corporation, needed a torsion control device to employ in its fuser roll cleaning system for a new line of copiers, it came to Reell Precision Manufacturing of St. Paul, MN. Reell, a recognized leader in small-package torque control solutions, had worked with Xerox before, supplying various electromechanical wrap-spring clutches that are widely used in copiers and other paper-handling devices. However, this time Xerox was looking for a passive torque control solution that was simple, inexpensive, and yet still reliable enough to work for tens of thousands of copy cycles.

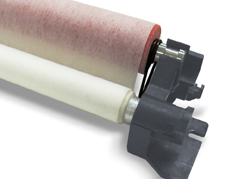

In a xerographic copier, an image is transferred to paper in a process that uses static electricity and a plastic-based toner “ink.” However, the image is not fixed until the paper goes through the fuser roll. The fuser roll is a heated drum that essentially melts the plastic-based toner and presses the copy image into the paper fibers to make it permanent. If toner debris builds up on the 400° F fuser roll, it can lead to dirty or streaked copies. To eliminate this tendency, the fuser roll is constantly wiped by a slowly moving web of fabric that cleans toner debris from the roll. Xerox was seeking a simple and reliable way of keeping tension on this moving fuser roll cleaning web.

No off-the-shelf solution

“The engineers at Xerox wanted a specific amount of torque or drag on the shaft that moved the fuser roll cleaning web,” says Joe Arnold, a Reell project engineer. He realized that what Xerox needed was not an off-the-shelf solution, but a custom precision spring that was designed, prototyped, tested and manufactured to produce the required torque when installed on the slow-moving fuser roll cleaning web shaft

“The engineers at Xerox wanted a specific amount of torque or drag on the shaft that moved the fuser roll cleaning web,” says Joe Arnold, a Reell project engineer. He realized that what Xerox needed was not an off-the-shelf solution, but a custom precision spring that was designed, prototyped, tested and manufactured to produce the required torque when installed on the slow-moving fuser roll cleaning web shaft

There are a variety of ways to apply torque to a slowly moving shaft, says Arnold, and over the years, copier manufacturers have tried multiple methods with varying success. “Wave springs and flat washers provide torque, as do plastic clips and other devices. But those devices are very difficult to adjust properly, and they change with wear and time,” he says. “Materials also make a lot of difference in torque control performance, as do lubricants if the revolutions are higher.”

Wire size key for maintaining torque tolerance

“In torque applications where you need to maintain precise interference with high tolerance, the rule is to always use the smallest diameter wire for the spring that will still deliver the right amount of torque,” says Arnold. “The reason is that the thinner spring wire makes it much easier to maintain interference within tolerance.”

“In torque applications where you need to maintain precise interference with high tolerance, the rule is to always use the smallest diameter wire for the spring that will still deliver the right amount of torque,” says Arnold. “The reason is that the thinner spring wire makes it much easier to maintain interference within tolerance.”

To illustrate the effect of wire diameter on tolerance, here are two examples involving springs made with different diameter wire, each producing 10 oz-in of torque when wrapped around a moving shaft:

• Spring “A” has a wire diameter of 0.040 inch and produces 10 oz-in of torque when wrapped around a moving shaft with 0.010 inch of interference. To maintain the interference (and therefore, torque) within +/- 10 percent, the interference can vary by +/- 0.001 inch over the life of the system – an achievable goal in the real world.

• Spring “B: has a wire diameter of 0.042 inch and produces 10 oz-in of torque when wrapped around a moving shaft with only 0.007 inch of interference. (The larger diameter wire produces a stronger spring which requires less interference to produce the same torque.) However, in order to maintain this smaller interference within a tolerance of +/- 10 percent, the interference now has to be kept to +/- 0.0007 inch – a much more difficult task.

Design plus precision manufacturing

In St. Paul, Reell uses a patented spring winding manufacturing process that produces some of the most precise and accurate springs in the industry. Springs made on the company’s unique piezo-based spring winding machines can hold spring diameter tolerances of +/- 0.0005 inch. When used in torque applications, this degree of precision translates into very reliable performance over time.

Xerox is manufacturing and marketing the new copier line primarily in Europe, while the design of the torque solution, prototyping, and manufacturing of the precision springs are taking place at Reell’s St. Paul, Minnesota headquarters. To facilitate shipping and delivery, the torque springs are channeled through Reell’s wholly owned subsidiary, Reell Precision Manufacturing B.V., in the Netherlands.

In most office environments, few other pieces of equipment get more constant use than a copier, and economical design improvements that improve its reliability, contribute to higher customer satisfaction. For Xerox and its new line of copiers, the addition of a simple precision wound torque spring from Reell Precision Manufacturing is resulting in many more clean and crisp copies.